Most of us put a lot of effort into preventing problems and mistakes from happening, but the truth is, they are – and always will be – an integral part of everything we do. What really matters, however, is how we approach them. In this article, Leszek Lipiński, a lean manufacturing expert and experienced manager, is going to provide an insight into common management approaches to problems in manufacturing companies, as well as some tips on problem-solving and introducing changes successfully.

ALLOW PEOPLE TO MAKE MISTAKES

Let’s start with something that might be considered an unpopular opinion. There are still a lot of managers with a very negative, rejecting approach to mistakes, which causes complications not only in the efforts to solve the problems but also in the relationships and overall atmosphere in the company. If the first question a manager asks when something happens is “Whose fault is this?”, employees will feel discouraged and will try to cover up things that go wrong. This means the problem will only become worse before it is finally detected.

Instead, it might be more beneficial to ask “What can we do to make it better?”. This way, people won’t be afraid to talk about their mistakes and problems. When asking this question (instead of looking for who is to blame), you will often come to a realization that your employees – whether they work on the production floor or in the planning department – know how to solve many of the issues themselves.

COLLECT DATA

Managers can’t make the right decisions without the right data. It’s therefore important to have systems in place to collect important information – and to make it accessible to all relevant people. Maybe you hold regular meetings with your staff or you have notice boards installed in the production area with key data. This enables you to not only identify potential abnormalities but also collect suggestions for improvement. Because introducing change isn’t just about solving problems – it’s also about improving current processes.

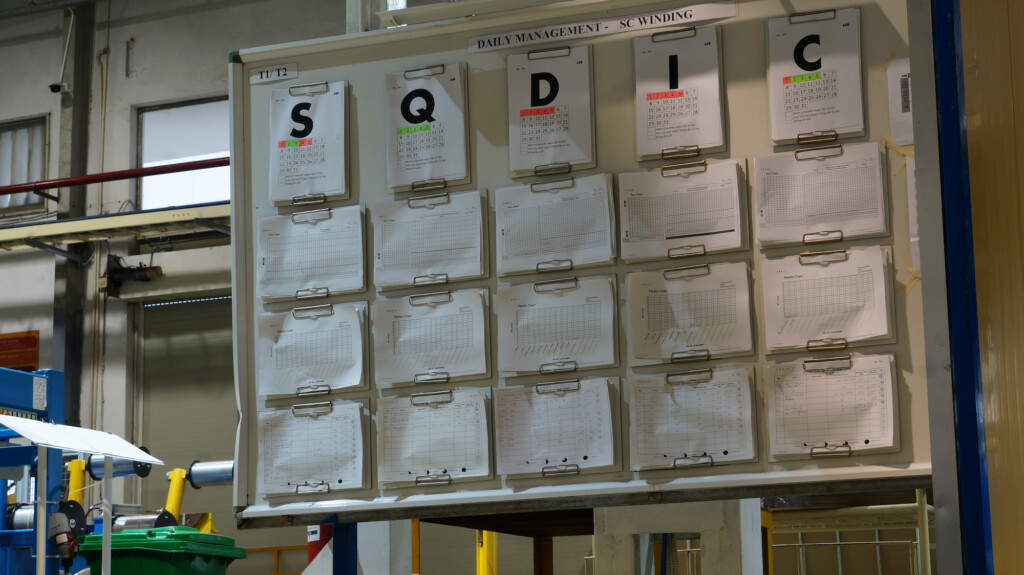

One of the common methods for collecting and sharing information is an SQDC board. It’s a very useful tool for daily process management. The board is placed in the production area and provides KPIs related to the process which are collected during regular meetings. Four main areas are covered: safety, quality, delivery and cost. This information is available to all workers. Using the board also helps you promote accountability: once a problem is recorded, the supervisor appoints the responsible person, and it’s easy to track progress.

TAKE ACTION

Once you’ve identified and recorded a problem, the next step is to fix it. Some actions are quite simple – you just go and solve the issue (e.g. fix a broken cable or install an extra light). Other problems require a more complex approach – sometimes you might not even know where the root cause is. In these cases, it is beneficial to run a workshop to identify the cause and come up with a possible solution as a team. It’s really important to involve your employees rather than trying to solve everything yourself. More complicated problems require advanced problem-solving methodologies such as Six Sigma.

But as was mentioned before, reactive projects (that are implemented to fix things) are only one part of introducing change. The other part proactive, or development, projects. According to kaizen philosophy, every company should constantly strive to be better, to continuously improve processes. Maybe you want to increase your production efficiency, reduce energy usage or increase the digitisation level of your company (such improvements are often requested by the business owners). No matter what the goals are and who set them, it is the pursuit of them that drives your business forward.

GET PEOPLE ON BOARD

Solving problems and introducing changes successfully isn’t a job for the managers only. It’s important to involve all the people in the company. For many employees, the feeling that they are heard and able to influence things is a very strong motivator. They feel empowered when they can take part in the process of change. Others, however, might have the “I’ll just do my job and that’s it” approach. Some employees might simply be unwilling to change their ways (resistance to change is actually a very common phenomenon – why should we change something that’s been working for ages?).

In these situations, I believe in the power of communication. It’s important to be transparent and inform employees even about unpopular decisions and changes. This prevents uncertainty and promotes trust and openness. It is absolutely essential though to make sure the message is clear and well understood.

Equally important is involving the right people from the beginning. These are so-called “informal leaders” who are well-respected among their coworkers. Once you manage to persuade them of the necessity and the benefits of the change, it will be easier to get other people on board and implement the change successfully. Identifying the informal leaders is another key step.

THE TAKEAWAY

- “Change is more about psychology than about technology.” Building a good relationship with your employees and creating an atmosphere of trust and accountability create the foundation for successful problem solving. It will be hard (if not impossible) to make up for a lack in this area by using advanced methodologies and state-of-the-art technologies.

- Problem-solving actions should go hand in hand with continuous improvement. It’s not just about issues to be fixed. It’s about identifying areas in which you can get better as a company. Together, as one team.

- If you’re not sure how to approach your situation, how to reduce the resistance to change in your company, how to solve some of your problems or achieve desired improvements, it might be worth considering getting advice from someone outside your organization. An experienced consultant has a portfolio of useful methods and tools that can help you get results more quickly and easily.